How to Commercially Make Almond Butter?

The raw material usually used to process almond butter is sweet almond, you can also use bitter almonds for processing. But the bitter almonds must be pre-precessed to detoxicate beforing used to make butter. Because the bitter almond contains amygdalin which can hydrolyze quickly in the water to produce gluconic and extremely poisonous hydrogen cyanide, when it is used in the production of almond butter, the bitter almond must be soaked in water, and frequently change the water to remove the hydrogen cyanide.

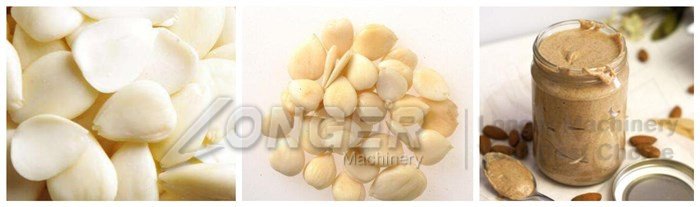

Almond shelling → Blanching peeled → Baking or Roasting → Grinding sauce → Cooling → Filling and Packaging.

LONGER Machinery offers the complete set of Almond butter production line:

LONGER Machinery offers the complete set of Almond butter production line:

(1) Choosing raw materials: Sweet almond or large flat varieties for the best, you can also use bitter almonds for processing. But must be bitter bitter bitter poison can be used, otherwise there is the risk of death. Because bitter bitter bitter bitter from the almond, when the amygdalin hydrolysis can produce glucose and highly toxic hydrogen cyanide, so when the use of bitter almond processing, must be soaked in water, and often change the water to Remove the hydrogen cyanide.

(2) Almond Shelling: the use of almond shelling machine to remove the hard shell. We also provide three apricot shells, apricot kernel can be divided into three levels by size to complete a shelling. Easy to operate, can fully meet the needs of small-scale dried fruit processing; small footprint, easy to line production.

(3) Blanched peeling: the material boiled with boiling water for 2-3 minutes to remove the apricot seed coat, such as bitter almonds must check the bitter degree of raw materials, require no bitter taste in the mouth, before feeding processing.

(4) Grinding sauce: colloid mill the most suitable for grinding sauce, the peeled almonds into the mill for grinding sauce, a rough grinding, grinding into medium fineness, 2 fine grinding, grinding into a fine smooth finished The Add 2 drops of sugar or salt (2% to 3% sugar, 0.5% salt) and 0.05% vitamin E

(5) Filling: Filling the bottle by weight. Almond paste filling machine by the PLC with man-machine interface (touch screen) control, novel design, compact structure, beautiful appearance. With accurate measurement, friendly interface, stable and reliable performance, high degree of automation, simple operation, easy maintenance and so on.

E-Mail

E-Mail Whats

Whats TOP

TOP