Pumpkin Seed Shelling Processing Line Sold to Mexico

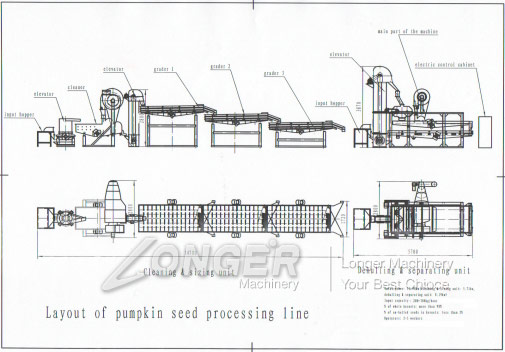

Melon seeds shelling processing line is manufactured by LONGER Machinery, which is with independent intellectual property rights and can be used to process white melon seeds (pumpkin seeds, horns seeds), watermelon seeds, Trichosanthes konjac, melon seeds,etc. The complete melon seeds shelling processing line is consisted of two parts: Grading unit and shelling sorting unit.

The grading unit can pumpkin seeds, horned melon seeds, watermelon seeds, melon seeds, melon seeds, hanging melon seeds and gourd seeds to clean up, remove all kinds of impurities, and then the seeds by size divided into seven levels to carry out shelling.

The grading unit can pumpkin seeds, horned melon seeds, watermelon seeds, melon seeds, melon seeds, hanging melon seeds and gourd seeds to clean up, remove all kinds of impurities, and then the seeds by size divided into seven levels to carry out shelling.

The shelling unit can be divided into pumpkin seeds, horny melon seeds, watermelon seeds, melon seeds, melon seeds, hanging melon seeds and gourd seeds, respectively, for shelling, skin removal, sorting, one of which is not off Of the grain can be automatically returned to the shelling machine to re-shell, until the release date. As a result of the first classification after the shelling, so the shelling sorting effect is very good, high efficiency.

The main features of melon seed shelling processing line:

① Using wet hulling

② Through the original shelling machine improvements, so that the higher efficiency of the shell and nuts broken rate is lower.

③ Application of the cycle of shelling, that is, no shelling seeds automatically into the next shelling cycle;

④ In the collection of leather processing, the use of vibration negative pressure sorting instead of blowing way, reducing the dust generation.

⑤ Increase the sorting sieve and screening area, so that can be fully sieved, to reduce the kernel back to the shell caused by crushing,

⑥ It can be replaced by screening sieve section, processing different specifications of white melon seeds.

⑦ Compact structure, low loss, easy operation and maintenance

Melon seed shelling processing line is used to improve the husking effect:

Sieve selection of high-quality cold-rolled steel plate made of, durable.

The following elastic ball design reduces the paste hole phenomenon.

Lengthened, widened sorting screen so that nuts are sorted more thoroughly.

The use of vibrating negative pressure sorting machines and screw unloaders facilitates the collection of leather and reduces the generation of dust.

The vibration source of the whole set of equipment adopts the form of vibration motor, the equipment is easy to install, and the foundation is not needed quickly

The grading unit can pumpkin seeds, horned melon seeds, watermelon seeds, melon seeds, melon seeds, hanging melon seeds and gourd seeds to clean up, remove all kinds of impurities, and then the seeds by size divided into seven levels to carry out shelling.

The shelling unit can be divided into pumpkin seeds, horny melon seeds, watermelon seeds, melon seeds, melon seeds, hanging melon seeds and gourd seeds, respectively, for shelling, skin removal, sorting, one of which is not off Of the grain can be automatically returned to the shelling machine to re-shell, until the release date. As a result of the first classification after the shelling, so the shelling sorting effect is very good, high efficiency.

E-Mail

E-Mail Whats

Whats TOP

TOP