Fry Machine

Vacuum Fryer Process Machine|VKV-C Vacuum Snacks Fryer On Sale

- Material: Okra, mushroom, red radish,mushrooms,chips etc

- Capacity: 50-60 kg/time

- WhatsApp: 0086-18538123076

Description:

Vacuum frying machine is the practice of frying and dehydrating food at low temperature (80-120 °C), which can effectively reduce the damage of high-temperature food nutrients.

Features

Commercial Vacuum Frying Machine is the practice of frying and dehydrating food at low temperature (80-120 ° C), which can effectively reduce the damage of high-temperature food nutrients. Low-temperature vacuum frying can prevent the deterioration of the quality of edible oils and fats. It is not necessary to add other antioxidants, which can improve the repeated utilization rate of oil and reduce the cost.

The oil content of fried foods is as high as 40%-50%, and the oil content of vacuum fried foods. In 10%-15%, fuel saving 30%-40%, the fuel saving effect is remarkable, the food is brittle but not greasy, and the storability is good.Under vacuum, the water in the cell gap of fruit and vegetable is rapidly vaporized, expanded, the gap is enlarged, and the puffing effect is good. The product is crispy and delicious, and has good rehydration properties.

The oil content of fried foods is as high as 40%-50%, and the oil content of vacuum fried foods. In 10%-15%, fuel saving 30%-40%, the fuel saving effect is remarkable, the food is brittle but not greasy, and the storability is good.Under vacuum, the water in the cell gap of fruit and vegetable is rapidly vaporized, expanded, the gap is enlarged, and the puffing effect is good. The product is crispy and delicious, and has good rehydration properties.

Vacuum fryer overview:

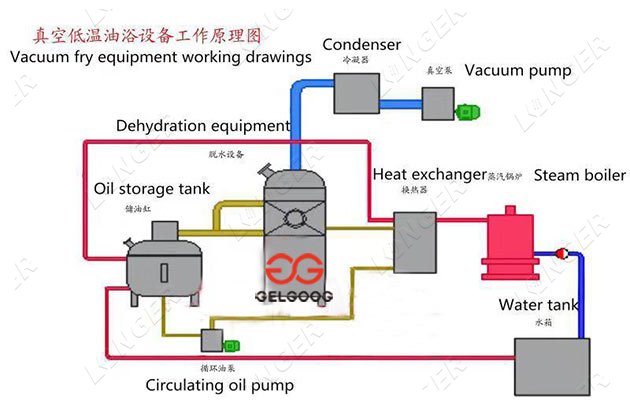

1. Learn from the independent research and development of Japanese technology. Heating, frying, oil storage, deoiling, dehydration, oil filtration integrated design, continuous completion under vacuum, product oil content is low, the product is in a negative pressure state, in this relatively oxygen-free conditions for food processing, It can reduce or even avoid the harm caused by oxidation (such as fatty acid loss, enzymatic browning and other oxidative deterioration). In the negative pressure state, oil is used as a heat transfer medium, and the moisture inside the food (free water and partially bound water) evaporates rapidly and ejects. Forming a loose porous structure into the tissue;

2. Automatic control of temperature and pressure (vacuum degree), no overheating, no overpressure, ensuring product quality and safe production;

3. Deoiling adopts frequency conversion speed regulation, suitable for all products with low oil content and high oil content;

4. The oil-water separation system can cool and separate the evaporated water oil, reduce the pollution of the water circulation, increase the repeated use rate of water, and reduce the loss of oil;

5. Oil filtration system: up and down oil tank, double chamber heating system, separate control heating, frying and filtering oil during frying, keep grease clean and reduce oil waste;

6. The machine is made of stainless steel and has the characteristics of high work efficiency, stable performance and convenient installation and use.

The vacuum fryer process:

Raw material cleaning and peeling - slicing - cutting strips - killing (blanching and color protection) - dehydration - quick freezing - vacuum frying - vacuum deoiling - seasoning - product packaging - storage

Technical Data

| Model | LG-320 | LG-500 | LG-800 | LG-1000 | LG-1200 |

| Specifications | Φ320 mm | Φ500 mm | Φ800 mm | Φ1000 mm | Φ1200 mm |

| Material box sizes | Φ300*200 mm | Φ500*460 mm | Φ800*500 mm | Φ1000*600mm | Φ1200*600 mm |

| Material box number | 2 | 2 | 2 | 2 | 2 |

| Vacuum degree of work | 0.096-0.098 mpa | 0.096-0.098 mpa | 0.096-0.098 mpa | 0.096-0.098 mpa | 0.096-0.098 mpa |

| Working Temperature | 80-120 C | 80-120 C | 80-120 C | 80-120 C | 80-120 C |

| Vacuum pump power | 5.5 Kw | 11 Kw | 11 Kw | 11+3 Kw | 11+3 Kw |

| Heating mode | electrical | electrical/steam | electrical/steam | electrical/steam | electrical/steam |

| Volume | 14 L | 90 L | 250 L | 470 L | 680 L |

|

Production (french fries,for example) |

5-6 Kg/Time | 35-40 Kg/Time | 95-100 Kg/Time | 190-200 Kg/Time | 280-300 Kg/Time |

| Installed capacity | 30 Kw | 20.5 Kw | 20.5 Kw | 23.5 Kw | 23.5 Kw |

| Overall dimensions | 1400*1400*1900 mm | 2400*2400*2400 mm | 3600*3200*3000 mm | 3800*3600*3000 mm | 4200*3800*3400 mm |

Message

Thank you for visiting our site! Please feel free to submit this form with any questions or comments. We will answer your message within 24 hours.

Related Products See More

Get Price

SEND EMAIL

SEND EMAIL GET PRICE

GET PRICE

E-Mail

E-Mail Whats

Whats TOP

TOP