Starch Plant

Automatic Cassava Starch Production Line

- Material: 1 Set

- Capacity: 100 Set/Sets Per Month

- Loading Port: Qingdao Port

Description:

1 Cassava receiving, transporting and cleaning unit Store the cassava in storage pool. Then the de-stone machine will remove the dirt and other foreign matters completely. Finally, store the clean cassava in a temporary storage hopper. 2 Cassava rasping unit The rasping unit is the most important part of cassava starch extraction. Rasping mill with high efficiency allows the starch granules in the cassava cells to be released out completely, which ensures minimum quantity of the remaining starch

Features

1 Cassava receiving, transporting and cleaning unit

Store the cassava in storage pool. Then the de-stone machine will remove the dirt and other foreign matters completely. Finally, store the clean cassava in a temporary storage hopper.

2 Cassava rasping unit

The rasping unit is the most important part of cassava starch extraction. Rasping mill with high efficiency allows the starch granules in the cassava cells to be released out completely, which ensures minimum quantity of the remaining starch in the cassava residue. The rasping cassava slurry is pumped into de-sanding unit by a fiber pump.

3 De-sanding unit

Rasping cassava slurry is pumped through the fiber pump into the de-sanding cyclone. When the slurry enters de-sanding cyclone, the light phase of starch and cassava residue come out of the top as overflow, and the heavy phase like sands will be discharged from the bottom.

4 Starch extracting unit

Centrifugal extraction is another key unit which influences the cassava starch yields. The cassava slurry enters the first stage centrifugal sieve from de-sanding cyclone, the slurry is separated into starch slurry and cassava residue under the centrifugal force. Starch slurry is pumped through the de-foaming pump to the hydro-cyclone station for washing starch, and the cassava residue is sent to second and third grade centrifugal sieves through fiber pump for starch recovery.

5 Cassava residue dewatering

We use a centrifugal sieve for cassava residue dewatering, it works like the extraction sieve. Finally, cassava residue is transported out of the workshop, the extracted water return to the process water system.

Store the cassava in storage pool. Then the de-stone machine will remove the dirt and other foreign matters completely. Finally, store the clean cassava in a temporary storage hopper.

2 Cassava rasping unit

The rasping unit is the most important part of cassava starch extraction. Rasping mill with high efficiency allows the starch granules in the cassava cells to be released out completely, which ensures minimum quantity of the remaining starch in the cassava residue. The rasping cassava slurry is pumped into de-sanding unit by a fiber pump.

3 De-sanding unit

Rasping cassava slurry is pumped through the fiber pump into the de-sanding cyclone. When the slurry enters de-sanding cyclone, the light phase of starch and cassava residue come out of the top as overflow, and the heavy phase like sands will be discharged from the bottom.

4 Starch extracting unit

Centrifugal extraction is another key unit which influences the cassava starch yields. The cassava slurry enters the first stage centrifugal sieve from de-sanding cyclone, the slurry is separated into starch slurry and cassava residue under the centrifugal force. Starch slurry is pumped through the de-foaming pump to the hydro-cyclone station for washing starch, and the cassava residue is sent to second and third grade centrifugal sieves through fiber pump for starch recovery.

5 Cassava residue dewatering

We use a centrifugal sieve for cassava residue dewatering, it works like the extraction sieve. Finally, cassava residue is transported out of the workshop, the extracted water return to the process water system.

Technical Data

| Cassava Starch Production Line with capacity 500kg/h | ||||

| Serial number | Machine name | model | quantity | note |

| 1 | Cage model cleaning machine | LG-4000*800 | 1set | 3kw carbon steel material |

| 2 | Automatical feeding model cleaning machine | GG-500*3700 | 1set | 3KW carbon steel material |

| 3 | Hammer Crusher | LG-520C | 1set |

18.5kw carbon steel material Capacity: 3-4t/h (cassava) |

| 4 | Cylinder separating machine | LG-450B | 3sets | 4kw*3=12kw,carbon steel material  |

| 5 | Litter cleaning machine | LG-CX-4 | 1set | 2.2kw stainless steel |

| 6 | conveyor | LG-380*4000 | 2sets | 2.2KW carbon steel material |

| 7 | Rotation flowing model separating machine | LG-1 | 1 group | 35KW carbon steel material |

| 8 | Vacuum Dewatering machine | LG-TS-C | 1set | 15KW filtering area: 12 m2 |

| 9 | Drying machine | LG-B | 1 group |

25kw,carbon steel material Coal consuming:30KG/h  |

Message

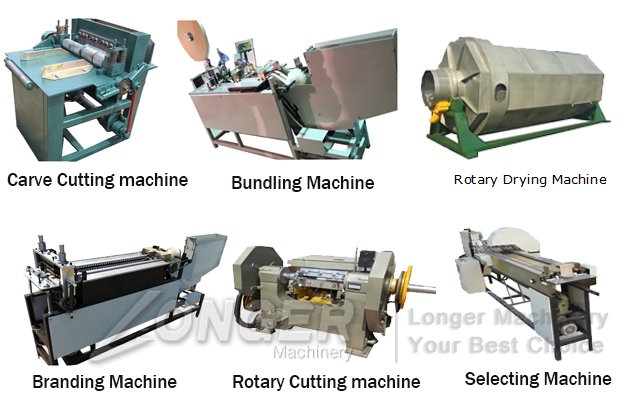

Related Products