Snacks Machiney

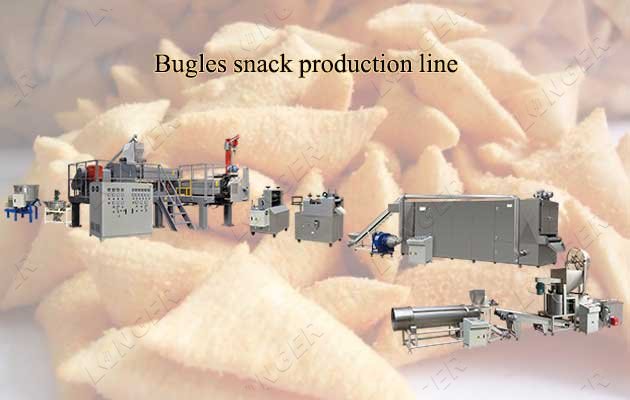

Bugles Snack Production Line|Puffed Snack Extruding Plant

- Material:

- Capacity: 300~400kg/h

- WhatsApp: 0086-18538123076

Description:

This bugles snack process line uses wheat flower,rice flour, and corn flours as the raw material to produce flour food by screw extrusion technique. By using different moulds, the production line can make different final snacks, such as rice crust, pillow, pizza roll, shell, whelk, cat-ear, pea, triangle etc.

Features

This bugles snack process line uses wheat flower,rice flour, and corn flours as the raw material to produce flour food by screw extrusion technique. By using different moulds, the production line can make different final snacks, such as rice crust, pillow, pizza roll, shell, whelk, cat-ear, pea, triangle etc.

Work flow: Raw material mixing → conveying → extrusion puffing material → embossing molding → frying → seasoning → cooling and packaging

Work flow: Raw material mixing → conveying → extrusion puffing material → embossing molding → frying → seasoning → cooling and packaging

Features of puffed snacks making equipment:

1. Made of stainless steel, which enable the machine to have high quality and long service life.

2. Stable running and good performance.

3. Economical and practical, superior quality and competitive price.

4. Advanced technology guarantees the machine to have low energy cost and labor cost.

5. The land required to install this production line is about 50 square meters.

High pressure double crank to control the die opening and closing.

Running in a high automatization and intellectualization,no pollution

Apply a linker to connect with the air conveyor ,which can directly inline with filling machine.

Technical Data

| Bugles snack production line | |

| Mixer | Power: 5.5kw |

| Dimension:1350*1050*1200mm | |

| Capctiy: 100kg/time | |

| Vacuum lifter | Power: 5.5kw |

| Capctiy: 1000kg/h | |

| Dimension:650*600*5500mm | |

| Cooling column | Power: 0.67kw |

| Dimension:900*900*1850mm | |

| Extruder (single screw) | Capacity:350kg/h |

| Dimension:5000*4500*4000mm | |

| water-injection | Power: 2.92kw |

| Dimension:900*660*1600mm | |

| Forming machine | Dimension:1350*1250*1300mm |

|

Five layers oven |

Capacity:300~500kg/h |

| Heating temprature:0~120℃ | |

| Drying time:2~3h | |

| Dimension:21000*2100*3030mm | |

| Rotating thermal separator | Power: 0.75kw |

| Dimension:1500*1300*1900mm | |

| Cooling Conveyor | Dimension:5000*1150*800mm |

| Continuous fryer | Capacity:300~400kg/h |

| Dimension:4000*1350*2200mm | |

| Deoiling machine | Capacity:300~400kg/h |

| Dimension:1600*1000*1850mm | |

| Dimension:4000*1350*2200mm | |

| Flavoring line | Capacity:300~400kg/h |

| Dimension:4300*1800*1850mm | |

| Packaging | |

Message

Thank you for visiting our site! Please feel free to submit this form with any questions or comments. We will answer your message within 24 hours.

Related Products See More

Get Price

SEND EMAIL

SEND EMAIL GET PRICE

GET PRICE

E-Mail

E-Mail Whats

Whats TOP

TOP