Snacks Machiney

Corn Flakes Extruding Line Price|Automatic Corn Flakes Machine

- Material: corn|maize flour,sugar,salt,other nutrients

- Capacity: 100-200kg/h

- WhatsApp: 0086-18538123076

Description:

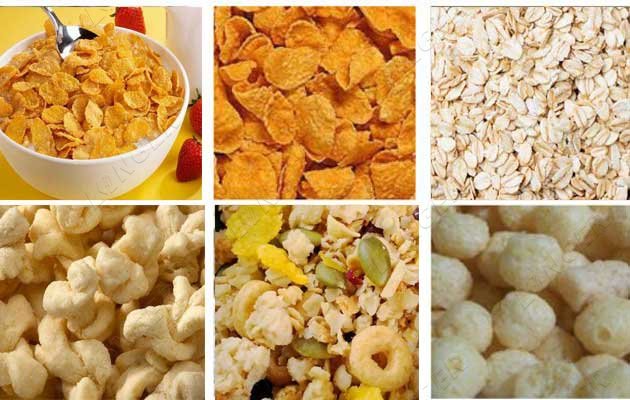

Corn Flakes Extruding Line produces corn flakes, breakfast cereals, and puff snacks similar to Kellogg and Nestle products, the shapes and sizes can be various. The production process of making corn flakes: Mixing materials - Extruding - Flaking - Drying - Toasting - Oil Spraying - Drying - Cooling.

Features

Corn Flakes Extruding Line produces corn flakes, breakfast cereals, and puff snacks similar to Kellogg and Nestle products, the shapes and sizes can be various. The production process of making corn flakes: Mixing materials - Extruding - Flaking - Drying - Toasting - Oil Spraying - Drying - Cooling.

The main machines for corn flakes are: Mixer, Extruder, Flakes forming machine, Drying oven, Oil spraying, High-temprature Drying Oven, Cooling, Packaging Machine and some conveyors, air conveyor etc.

- Powder Mixer Equipment: 304 stainless steel material of the drum shell, steel blade stirring blade, corn flour added nutritional additives and a certain proportion of water to mix evenly.

- Double-screw extruder: The advanced twin-screw extruding structure is adopted, and the end of the screw adopts an elongated shear screw sleeve, which can make the material expand better.

- Three-layer fuel oven: The temperature of the oven is adjusted by the control cabinet between 0-200 degrees. The interior is a stainless steel double-layer net bag. The baking time can be adjusted according to the speed to remove moisture. There are three-layer, five-layer and seven-layer stainless steel ovens.

- Drum-type high-temperature oven: high-temperature baking, corn flakes crispy, sweet and delicious

- Drum-type oil spraying line is mainly used for spraying oil on the surface of corn flakes coming out of the baking oven to make the color, aroma and taste of corn flakes more distinctive

- Three-layer extended fuel oil oven: Drying the moisture of the finished product for the third time, extending the shelf life of the product

- Cooling machine: It is used to cool the products after baking, to ensure the quality of corn flakes after packaging and to extend the shelf life.

Technical Data

| Corn Flakes Extruding Line | |

| Mixer | 100kg/time |

| Power: 7.5kw | |

| Dimension:1400×1000×1200 mm | |

| Size of barrel:φ820×600 mm | |

| Extruder | Capacity: 100-160 kg/h |

| Power:41.45kw | |

| Power Consumption:29kw | |

| Dimension:3060×950×2050 mm | |

| Flaking machine | Power:15.37 kw |

| Dimension:1500×1250×2300mm | |

| Three - layer oil drying oven | Capacity:100-160 kg/h |

| Power:4.47kw | |

| Oil consumption:6~8 kg/h | |

| Heating temperature:0~140 ℃ | |

| Drying time:4~14 min | |

| Dimension:6500×1500×2500 mm | |

| Drum type toasting | Capacity:100-160 kg/h |

| Power:62.17kw | |

| Power Consumption:38kw | |

| Heating temperature:~250℃ | |

| Dimension:4100×1200×2000mm | |

| Oil spraying machine | Capacity:150-250 kg/h |

| Power:2.57kw | |

| Heating:22.2kw | |

| Three - layer extended fuel oil oven | Capacity:100-160 kg/h |

| Powder:5.1 kw | |

| Burner:1.2×105 kcal | |

| Oil consumption:6~8 kg/h | |

| Heating temperature::~140 ℃ | |

| Drying tem:5~15 min | |

| Dimension:9000×1500×2500 mm | |

| Cooling machine | Dimension: 4000×900×1200 mm |

Message

Thank you for visiting our site! Please feel free to submit this form with any questions or comments. We will answer your message within 24 hours.

Related Products See More

Get Price

SEND EMAIL

SEND EMAIL GET PRICE

GET PRICE

E-Mail

E-Mail Whats

Whats TOP

TOP