Biscuit Machine

Automatic Kurkure Snacks Making Machine|Cheetos Niknak Puffed Food Processing Line

- Material: dough water oil salt etc

- Capacity: 80-120kg/h

- WhatsApp: 0086-18538123076

Description:

LONGER Machinery offers the processing line of making kurkure. All the machines are made by food grade stainless steel. Longer machinery offers oversea install and debug the equipment, train the first-line operator and provide Operation/ Service/ Maintenance Manual.

Features

Kurkure snacks or cheetos/niknak is a special extruded snacks very crunchy and great in taste. They are made by a special extrusion process.LONGER Machinery offers the processing line of making kurkure. All the kurkure making machines are made by food grade stainless steel. Longer machinery offers oversea install and debug the kurkure snacks processing line, train the first-line operator and provide Operation/ Service/ Maintenance Manual.

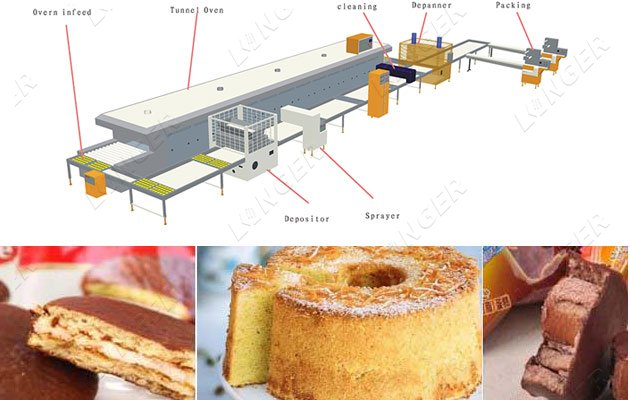

Flow chart of kurkure snacks processing line:

Mixing—Extrusion—Separating—Frying/Baking— Flavoring system

Equipment introduction of kurkure cheetos production plant:

1. Mixing machine: Add a certain proportion of water to the raw corn flour, rice flour, soy flour, fish meal, meat meal, cereal flour, additives, etc., and mix well.

2. Screw elevator machine: The motor is powered by spiral conveying, and the stirred raw material is sent to the feeding hopper of the twin-screw extruder. This equipment is convenient and quick to load, saving labor and high efficiency.

3. Kurkure extruder: Corn mash is mixed with a certain proportion of moisture and then enters the rotary head extruder. Under the action of the extrusion and squeezing of two rotary discs made of brass in the extruder, the corn mash forms an irregular twist shape. The cutter then cuts it into the desired length of product.

4. Conveyor: The produced feed pellets are transported into the multi-layer drying equipment.

5. Multi-layer oven: The oven is divided into electric oven, fuel oven, gas oven and steam oven. The temperature is adjusted between 0-150 degrees through the control cabinet. The inside of the oven is stainless steel mesh belt. The conveying is stable and the failure rate is low. The odd-expanded food is circulated through a multi-layer S-type orbit to dry the odd food to a safe moisture content and increase the shelf life.

6. Spray seasoning line: The oil sprayer sprays oil, flavor, etc. The seasoning tube has an octagonal cylinder, a cylinder, a lifting single drum, and a double drum seasoning line. According to the output and product nature, the grease is sprayed on the surface of the food while spraying. Minced meat and spices, sprinkle evenly.

8. Vibrating screen: Screen out excess external material and particle residue to ensure the quality and ensure the reuse of raw materials.

9. Packaging machine: Kurkure sealing automatic packaging machine can be used.

Technical Data

| Name | Technical parameter |

|

Mixing machine LGBF-1 |

Power: 3kw Capacity:25kg per time Dimension: 900*550*1250mm |

|

Screw Elevator LGSL-2 |

Power:1.1kw Capacity:350kg/h Dimension:2900*700*2300mm |

|

Kurkure Making Machine LGPS-3 |

Power:30kw Capacity:120-150kg/h Dimension:2200*830*2200mm |

Message

Thank you for visiting our site! Please feel free to submit this form with any questions or comments. We will answer your message within 24 hours.

Related Products See More

Get Price

SEND EMAIL

SEND EMAIL GET PRICE

GET PRICE

E-Mail

E-Mail Whats

Whats TOP

TOP