Biscuit Machine

Commercial Biscuit Making Machine Processing Line 150-200kg/h

- Material: flour,water,sugar,milk,egg,oil etc

- Capacity: 100-900kg/h

- WhatsApp: 0086-18538123076

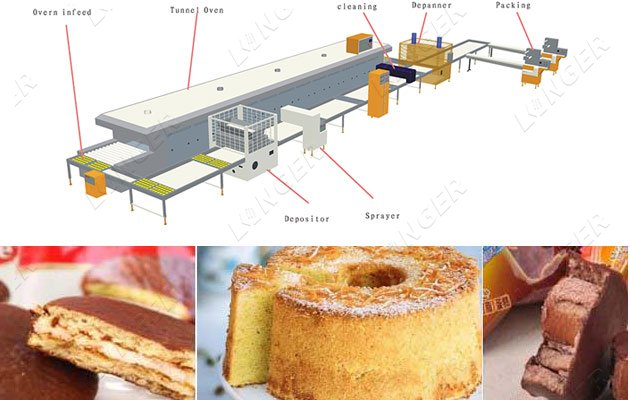

Description:

The 150-200kg/h industrial biscuits(hard biscuits) are mainly made of wheat flour, sugar (sugar-free) and oils and fats, with concave pattern on the surface.

Features

The commercial biscuit making machine production process of tough biscuits: Mixing flour with water, adding bulking agent, ameliorant and other auxiliary materials, and then forming, baking, cooling, stacking and packaging. The biscuits are mainly made of wheat flour, sugar (sugar-free) and oils and fats, with concave pattern on the surface.

Commercial biscuit making machine can make different shapes and sizes of biscuits by changing moulds.

Commercial biscuit making machine can make different shapes and sizes of biscuits by changing moulds.

1. Dough mixer: Mixing flour,water and other ingredients like sugar, milk, cream, oil, egg, etc

2. Rotary cutting machine:The device has continuous roll forming, stable operation, no impact, small vibration and noise, and no residual material. The whole machine is simple, compact and easy to operate.

3. Tunnel baking oven:The tunnel furnace is a kind of oven with a long furnace body, a narrow tunnel in the drying chamber, and a linear movement of food along the tunnel during the baking process. The structure of the oven: Furnace heating system transmission system ventilation and moisture system electronic control system

4. Oil spraying machine: The imported advanced frequency converter is used for stepless speed regulation, the oil spraying machine is with stable speed, and energy saving. The whole machine is mainly made of stainless steel and is in line with food hygiene. The angle of the fuel injection head can be adjusted, equipped with an automatic temperature control device, and can be sprayed at 360 degrees at the same time. Usually,we use palm oil ere for spraying the bisuits, oil temperature 50 ~ 60 ° C. Double-sided injection, fuel consumption 12% ~ 15%, oil can be used to reduce fuel consumption. Antioxidants should be added to the oil.

5. Cooling machine: The biscuits must be cooled to 38-40 ° C before they can be packaged. The standard of biscuits requires water content below 6.5%, so that the biscuits reach water content and extend the shelf life.

6. Biscuit stacking machine: It is equipped with a magnetic guiding platform that automatically tracks the position of the input biscuits, and is equipped with a magnetic and pin positioning combined with a fixed guide plate and a row partition.

7. Biscuit packaging machine: Pillow type biscuits packaging machine is a continuous packaging machine with strong packaging capacity and suitable for various specifications for food and non-food packaging. It can be used not only for the packaging of unbranded packaging materials, but also for high-speed packaging using reel materials with pre-printed logo patterns.

Video:

6. Biscuit stacking machine: It is equipped with a magnetic guiding platform that automatically tracks the position of the input biscuits, and is equipped with a magnetic and pin positioning combined with a fixed guide plate and a row partition.

7. Biscuit packaging machine: Pillow type biscuits packaging machine is a continuous packaging machine with strong packaging capacity and suitable for various specifications for food and non-food packaging. It can be used not only for the packaging of unbranded packaging materials, but also for high-speed packaging using reel materials with pre-printed logo patterns.

Video:

Technical Data

| Machine | Parameters |

| Dough mixer |

Power:5.5kw Voltage:380v50hz Dimension:1250*740*1300mm Time of mixing:10-15min Material:Inner hopper stainless steel |

| Biscuit forming machine(Rotary cutter) |

Power:2.2kw Dimension:1800*1000*1250mm Capacity:150-200kgh Weight:500kg |

| Tunnel baking oven |

Heating method:Electricity/GasPower:100-120kw Dimension:20000*1000*1300mm Weight:8000kg |

| Oil spraying machine |

Power:2.2kw Dimension:1800*1000*1850mm Weight:500kg |

| Cooling machine |

Power:1.1kw Dimension:10000*700*800mm Weight:600kg Raw material:Stainless steel |

| Biscuit stacking machine |

Power:2.2kw Voltage:380v50hz Dimension: 2600*1000*1200 Weight:700kg |

| Biscuit packaging machine |

Size of bag:(L)100-320mm (W)30-160mm (H)5-55mm Packing speed:50-250pcs/min Film width:90-360mm Power:4.1kw Weight:500kg Dimension:4100*950*1650mm |

Message

Thank you for visiting our site! Please feel free to submit this form with any questions or comments. We will answer your message within 24 hours.

Related Products See More

Get Price

SEND EMAIL

SEND EMAIL GET PRICE

GET PRICE

E-Mail

E-Mail Whats

Whats TOP

TOP