Biscuit Machine

Industrial Crispy Biscuit Cookies Making Production Line

- Material: flour,sugar,cream,oil,milk,egg etc

- Capacity: 150-200kg/h

- WhatsApp: 0086-18538123076

Description:

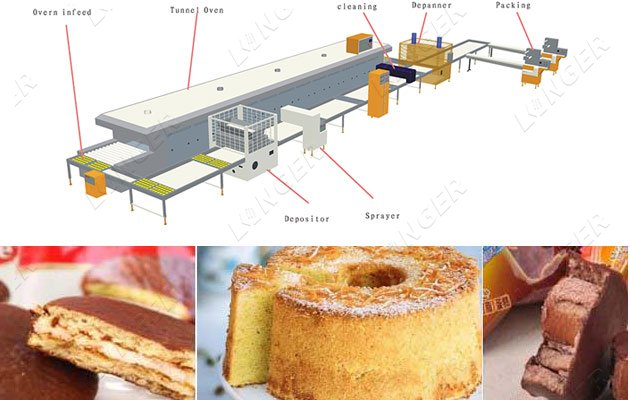

Industrial biscuit cookie production line consists of Dough mixer, Rotary moudling machine,Biscuit Tunnel oven, Oil spraying machine, Cooling conveyor, Biscuit stacking machine, Biscuit packaging machine.

Features

Industrial biscuit cookie production line consists of Dough mixer, Rotary moudling machine,Biscuit Tunnel oven, Oil spraying machine, Cooling conveyor, Biscuit stacking machine, Biscuit packaging machine. The cookie making machine is simple and convenient to operate, and all kinds of machinery are equipped with frequency conversion speed regulation.

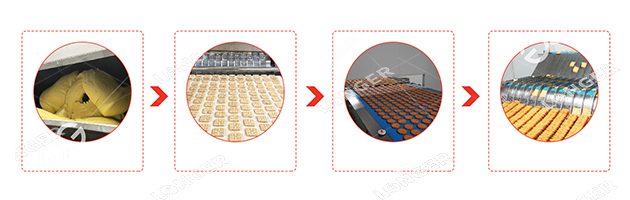

The production process of short biscuits(crispy biscuits) : Raw material - Mixing - Forming - Baking - Cooling - Biscuits stacking - Biscuits packaging. The industrial biscuit production line made by LONGER Maachinery can do different shapes and sizes biscuits and cookies by changing moulds, with novel equipment design, compact structure and high degree of automation. We can provide reasonable design configuration according to the customer's site, output requirements and electrical requirements to achieve customer satisfaction.

The production process of short biscuits(crispy biscuits) : Raw material - Mixing - Forming - Baking - Cooling - Biscuits stacking - Biscuits packaging. The industrial biscuit production line made by LONGER Maachinery can do different shapes and sizes biscuits and cookies by changing moulds, with novel equipment design, compact structure and high degree of automation. We can provide reasonable design configuration according to the customer's site, output requirements and electrical requirements to achieve customer satisfaction.

The notes of industrial biscuit production line:

1. When mixing low gluten wheat flour, water, sugar, milk, cream, oil, egg, the proportion of oil and sugar is Oil:Sugar=1:2; and Oil+Sugar: Flour = 1:2. The temperature of the finished batter is 26-28℃. The mixing time is 10-15 minutes.

1. When mixing low gluten wheat flour, water, sugar, milk, cream, oil, egg, the proportion of oil and sugar is Oil:Sugar=1:2; and Oil+Sugar: Flour = 1:2. The temperature of the finished batter is 26-28℃. The mixing time is 10-15 minutes.

2. The rotary moulding machine is continuous roll forming, stable operation, no impact, small vibration and noise, and no residual material. The whole machine is simple, compact and easy to operate.

3. The drive system of the tunnel baking oven transports the oven products and makes them have a suitable residence time in the oven to ensure the baking quality of the products. The transmission system includes the furnace belt, the transmission, the deviation adjustment mechanism, etc.

3. The drive system of the tunnel baking oven transports the oven products and makes them have a suitable residence time in the oven to ensure the baking quality of the products. The transmission system includes the furnace belt, the transmission, the deviation adjustment mechanism, etc.

Technical Data

| Model | GG-BG400/420 | GG-BG600 | GG-BG800 | GG-BG1000 | GG-BG1200 |

| Capacity | 100-250kg/h | 250-400kg/h | 500-800kg/h | 800-1000kg/h | 800-1200kg/h |

| Inner Width of Tunnel Oven | 400/420mm | 600mm | 800mm | 1000mm | 1200mm |

| Heating Method | Electric,Gas | Electric,Gas | Electric,Gas,Diesel | Electric,Gas,Diesel | Electric,Gas,Diesel |

|

Dimensions (without packing machine) |

L45m*W5m*H2m | L50m*W5m*H2m | L100m*W5m*H2.5m | L105m*W12m*H3m | L120m*W15m*H3m |

| Voltage | 380V 50HZ 3PH | 380V 50HZ 3PH | 380V 50HZ 3PH | 380V 50HZ 3PH | 380V 50HZ 3PH |

Message

Thank you for visiting our site! Please feel free to submit this form with any questions or comments. We will answer your message within 24 hours.

Related Products See More

Get Price

SEND EMAIL

SEND EMAIL GET PRICE

GET PRICE

E-Mail

E-Mail Whats

Whats TOP

TOP