Biscuit Machine

LGHG-27 Automatic Wafer Biscuit Production Line

- Material: wheat flour,oil,soda,water,sugar,cream

- Capacity: 2tons/24hours(day),can be customized

- WhatsApp: 0086-18538123076

Description:

Automatic Wafer Production line with two kinds of modes,GAS Heating and Electric Heating,energy saving,high production capacity,high automation,high recycle.

Features

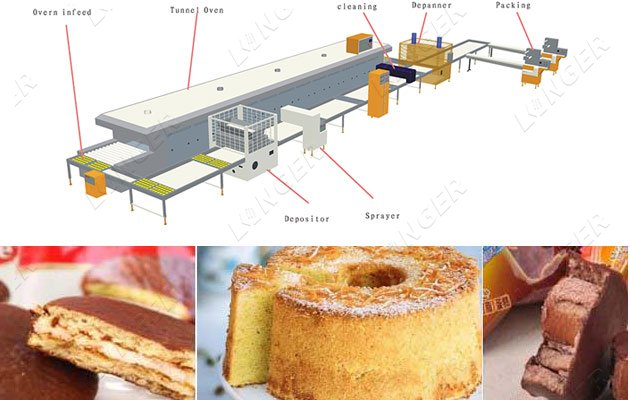

The working process of making wafer biscuit: Flour weighting water measuring, batter mixing, baking oven, wafer sheet cooling, cream mixing, cream spreading, wafer booking cooling with refrigeration, cutting, districuting and packaging. LGHG-27 High Quality Automatic Wafer Production Line is with 27moulds, capacity 2 tons/day, power consumption 120kw for electric type and 13kg/h gas for as type.

The total wafer biscuit production line is with stable performance, high output,low energy comsuption,convenient to use and maintain,easy to operate.

The electrical and mechanical components are used in international / domestic brands, longer brand,longer lifespan.

All parts in contact with food are made of 304 stainless steel, food grade PU belt, in line with health and safety standards.

The standard size of the baking plate is 470*325mm; Pattern(standard) is 2.5*2.5*0.5mm; Weight of wafer sheet: 50---60g; Wafer sheet's thickness: 2.2mm---3.2mm;

After sales service on wafer biscuit prodution line:

1.Warranty period: One year.

2.Installation: we will send our trained specialists to install the machines and train the customer's worker when the equipments are arrived in the client's city.

3. If the machines have something problem in running, we will help you to solve the problem anytime.

Video:

Video:

Technical Data

| No. | Equipment Name |

Dimension(mm) (L*W*H) |

Power | Qty |

| 1 | Batter Mixer | 1720*1200*930 | 4.5Kw | 1 |

| 2 | Gas Baking Oven (LGHG-27) | 6740*1600*2260 | 5.52Kw | 1 |

| 3 | Wafer sheet connecting machine | 1050*700*940 | 0.18Kw | 1 |

| 4 | Vertical-type wafer sheet cooler LPL | 3250*700*2780 | 0.37 Kw | 1 |

| 5 | Sheet Collecting Machine | 2000*700*825 | 0.18Kw | 1 |

| 6 | Cream spreading machine | 3000*1160*1300 |

380V-2.24Kw 220V-2Kw |

1 |

| 7 | Vertical cooling tower | 3140*1160*2700 | 1.21Kw | 1 |

| 7-1 | Cold Blower | 2200*1100*1800 | 10.75Kw | 1 |

| 8 | Laminator/Transportation system | 1115*700*870 | 0.18Kw | 1 |

| 9 | Mechical Blade-type Cutting Machine | 2000*1700*880 | 0.75Kw | 1 |

| 10 | Distributing machine | 1 | ||

| 10-1 | Separating conveyor | 1840*850*1350 | 0.18Kw | 1 |

| 11 | Cream Mixer(with water jacket) | 1830*700*1240 | 5.05Kw | 1 |

| 12 | Smashing machine | 670*660*1200 | 3Kw | 1 |

Message

Thank you for visiting our site! Please feel free to submit this form with any questions or comments. We will answer your message within 24 hours.

Related Products See More

Get Price

SEND EMAIL

SEND EMAIL GET PRICE

GET PRICE

E-Mail

E-Mail Whats

Whats TOP

TOP